Welcome to our company

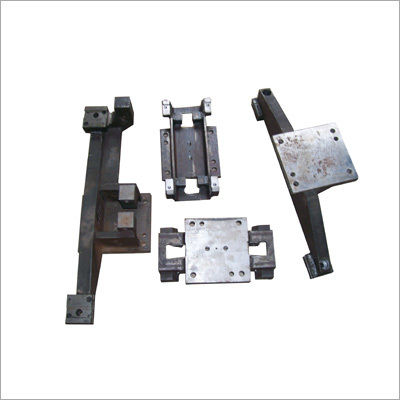

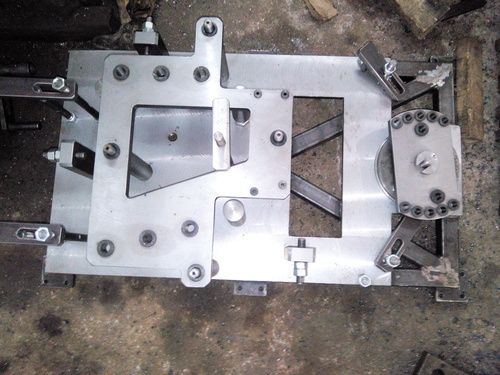

Conventional Jigs Fixtures

1000.00 - 10000.00 INR/Piece

Product Details:

- Die Head Standard precision die head

- Shaping Mode Customizable to specific component geometries

- Material Hardened alloy steel and tool steel

- Application Drilling, tapping, milling, assembly, and inspection operations

- Tolerance 0.01 mm or as per requirement

- Click to View more

X

Conventional Jigs Fixtures Price And Quantity

- 1000 Unit

- 1000.00 - 10000.00 INR/Piece

Conventional Jigs Fixtures Product Specifications

- Customizable to specific component geometries

- 0.01 mm or as per requirement

- Drilling, tapping, milling, assembly, and inspection operations

- Standard precision die head

- Hardened alloy steel and tool steel

Conventional Jigs Fixtures Trade Information

- 10000 Unit Per Day

- 10-15 Days

- No

- All India

Product Description

Backed by a diligent team of professionals, we have been able to manufacture and supply our clients a high quality range of Conventional Jigs Fixtures that is used in various industries. These are manufactured by our professionals as per the latest market trends using high grade metal alloy and advanced machinery. Widely acclaimed and demanded by our clients due to their sturdy construction, durability, dimensional accuracy and fine finish, the offered Conventional Jigs Fixtures are available in different specifications at market leading prices.

Tailor-Made Fixture Solutions for Precision Engineering

Our jigs and fixtures are customizable to meet specific component geometries and operational requirements. With a robust design and stringent manufacturing standards, our products deliver precision and reliability in various industrial processes. From assembly lines to inspection labs, these fixtures ensure optimal component alignment and repeatable accuracy.

Durable Materials and Enhanced Surface Finish

Constructed from hardened alloy steel and tool steel, our fixtures are built to withstand rigorous applications while maintaining long-term performance. The ground and polished finish not only strengthens corrosion resistance but also upholds cleanliness and appearance, which plays a crucial role in demanding production environments.

FAQs of Conventional Jigs Fixtures:

Q: How do I choose the right type of jig or fixture for my application?

A: Selection depends on your specific operationdrilling, tapping, milling, assembly, or inspection. Consider the components geometry, required tolerance (0.01 mm or as specified), fixture type (base plate, angle plate, or custom), and required weight capacity (up to 500 kg). Our team provides assistance to ensure the best fit for your process.Q: What benefits does the ground and polished surface finish provide?

A: A ground and polished finish greatly improves corrosion resistance, extends the fixtures lifespan, and reduces surface roughness. It also ensures consistent quality and cleanliness, which is indispensable in precision manufacturing environments.Q: When should I request a custom-designed fixture?

A: Custom designs are advisable when your component geometry or specific process requirements cannot be met by standard base or angle plate configurations. Customization allows for nuanced adaptation in shape, mounting, and compatibility with other equipment.Q: Where can these fixtures be mounted in a workshop or facility?

A: Our jigs and fixtures can be easily mounted either on benches or directly on machines, depending on your workspace setup and operational requirements. This dual mounting flexibility simplifies integration into existing workflows.Q: What is the manufacturing process for achieving ISO 2768/m compliance?

A: Fixtures are produced under strict quality norms, precisely machined, and finished to ISO 2768/m standards. This process includes careful material selection, exact machining, surface grinding, polishing, and rigorous inspections to guarantee desired tolerances and repeatability.Q: How are these fixtures typically used in industrial operations?

A: They are widely used to hold, align, and support components during drilling, tapping, milling, assembly, and inspection procedures, ensuring repeatability and high accuracy in production.Q: What advantages do I gain by using your fixtures for high-precision work?

A: By choosing our jigs and fixtures, you benefit from enhanced dimensional accuracy, accelerated setup times, extended fixture life due to robust materials and surface treatment, and flexible customization to meet varied operational needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free