Welcome to our company

Welding Fixtures

1000.00 - 10000.00 INR/Piece

Product Details:

- Working Process Welding assembly localization and positioning

- Die Head Interchangeable, precision machined

- Shaping Mode Custom steel fabricated

- Application Automotive parts, Heavy machinery, Sheet metal industries

- Tolerance 0.02 mm, depends on fixture complexity

- Click to View more

X

Welding Fixtures Price And Quantity

- 1000.00 - 10000.00 INR/Piece

- 1000 Unit

Welding Fixtures Product Specifications

- Automotive parts, Heavy machinery, Sheet metal industries

- Interchangeable, precision machined

- Welding assembly localization and positioning

- Custom steel fabricated

- 0.02 mm, depends on fixture complexity

Welding Fixtures Trade Information

- 10000 Unit Per Day

- 10-15 Days

- No

- All India

Product Description

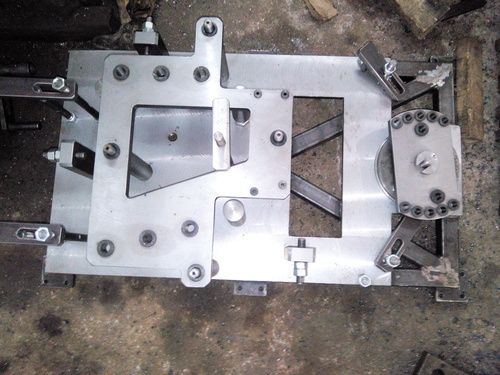

Amidst our wide range of products, we are also engaged in offering welding Fixtures that are used in various industries. These are manufactured using excellent quality metal alloy and latest machinery under the supervision of skilled professionals. The offered fixtures are highly appreciated for sturdiness, high strength, precise dimensions and durable finish standards. These welding Fixtures are available for our precious clients in standard as well as customized options at industry leading prices.

Advanced Design for Precise Welding

Leveraging 3D CAD optimization, our fixtures are crafted to minimize distortion and achieve superior precision during welding processes. The robust construction delivers consistent performance even in high-temperature environments, meeting the demands of tight tolerance assembly in automotive, heavy machinery, and sheet metal industries.

Tailored for Your Application

Every fixture is highly customizable, from overall size to the choice of clamps and accessories, ensuring compatibility with your unique welding process. Our solutions cater to MIG, TIG, and spot welding, providing versatile support for various industrial requirements and workpiece sizes.

Reliable and Adaptable Operation

Choose from manual, pneumatic, or hydraulic actuation based on your workflow, with all variants offering high repeatability up to 0.01 mm. Easy mounting on tables or baseplates and die head interchangeability further enhance operational flexibility and process efficiency.

FAQs of Welding Fixtures:

Q: How do I select the optimal welding fixture type for my process?

A: The choice between manual, pneumatic, or hydraulic fixtures depends on your workflow, workpiece size, and production volume. Manual fixtures suit smaller scale or low-volume applications, while pneumatic and hydraulic versions offer faster clamping and repeatability for higher production and larger assemblies.Q: What benefits does 3D CAD-optimized fixture design offer for welding?

A: Utilizing advanced 3D CAD design allows fixtures to be engineered for minimal distortion and precise localization, significantly improving accuracy and repeatability. This ensures your welds consistently meet tight tolerance requirements, reducing rework and enhancing product quality.Q: When is customization necessary for welding fixtures?

A: Customization becomes essential when you need to accommodate specific component sizes, complex geometries, or specialized clamping and accessories for unique applications. Our team works directly with you to design fixtures tailored to your exact welding process needs.Q: Where can these welding fixtures be installed and used?

A: Designed for adaptability, our fixtures can be mounted on standard welding tables or customized baseplates, enabling installation across a variety of production setups in automotive, heavy machinery, or sheet metal workshops throughout India.Q: What is the maximum weight and temperature these fixtures can handle?

A: Our fixtures support workpieces up to 2 tons and are engineered to withstand temperatures up to 350C, making them suitable for demanding industrial welding environments and continuous operation cycles.Q: How does the interchangeable die head feature improve the fixtures versatility?

A: Precision-machined, interchangeable die heads allow for quick adaptation to various part geometries and rapid changeovers between welding tasks, reducing downtime and boosting overall productivity in multi-product environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS